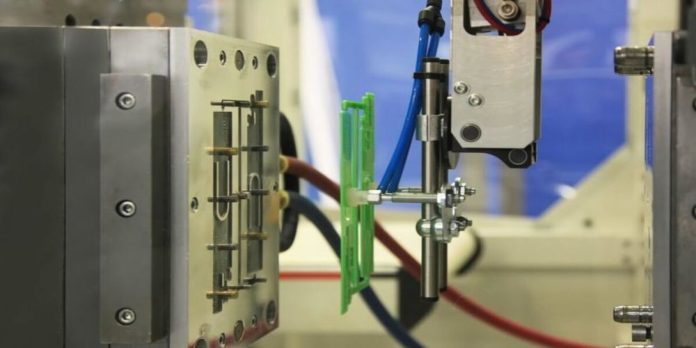

Every day people use plastics to make everything from automobile body parts to synthetic human body parts in a world that is always changing. Many companies use plastic injection molding to make important parts and make sure they work well.

There are many more plastic molding processes that you can use, each with its own set of advantages and features to meet the needs of different industries. It is up to the needs of the application to decide which molding process is best for a certain part.

What is Injection Molding?

A lot of different parts can be made with injection molding, both in size and shape. Also, the size of a press is based on how much pressure it has and how many tons it can make.

The basic principles of injection molding are very simple, but the process can be very complicated to ensure that the products always have the same quality. In this case, a mold made out of steel is used to get the melted plastic to go into the mold. After the molten plastic is injected into the mold, it fills all the holes, and the rest of the mold is filled with it. Pins are used to pushing the cooled pieces out.

Why Choose Plastic Injection Molding?

A lot of different things can be made with injection molding, from big parts for cars to small, delicate parts for surgical tools. Designers and engineers can make very complicated or unique things because there are so many different types of plastic resins and additives that can be used in injection molding. In addition, manufacturers who want to make parts that are even more unique can choose from a wide range of resin and finish options.

When the molds are made, production costs are much less than before. Once, it was clear that injection molding was the best way to produce high-volume, accurate parts because the price per piece dramatically drops as production starts.

Plastic injection molding is a great way to make lots of very precise and consistent parts in a large number of different sizes. It is more efficient and cheap because it doesn’t make as much waste as other molding methods. So, injection molding is the most common way to make high-volume, high-quality products.

Final Thoughts

People who make things with injection molding can make them in a wide range of sizes and shapes. It can make a wide range of parts, both size, and shape. It is more efficient and cheap because it doesn’t make as much waste as other molding methods. The process is ideal for making high-volume parts that are very accurate.

Plastic injection molding is becoming the most common way to make high-volume parts for cars, household appliances, medical devices, and a lot more, so it’s becoming more common. Materials you choose, how you make it, and how you deal with problems affect how well the production goes. People who know a lot about making high-volume parts with plastic injection molding should help you find a company that can do that. You can save time and money if you do this.